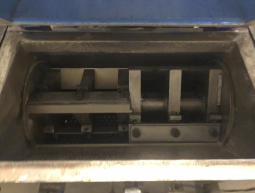

Granulator for polypropylene

Granulator for polypropylene, 400V/15kW, 280 à 330kg/h

This granulator machine is an essential tool for orthopedic centers looking to adopt a circular and sustainable production approach. Designed to crush and transform old prosthetics into reusable polypropylene granules, it helps reduce waste and optimize the use of existing materials.

An Eco-Friendly and Cost-Effective Process

With this granulator, centers can:

✔ Efficiently recycle used prosthetics, reducing dependency on new raw materials.

✔ Reuse the granules for manufacturing new mobility aids (crutches, orthopedic components).

✔ Lower material costs while minimizing environmental impact.

Technical Features

🔹 High processing capacity for fast and efficient production.

🔹 Powerful motor ensuring uniform crushing and optimized granule size.

🔹 Filtration system to remove impurities and ensure high-quality recycled material.

🔹 User-friendly and secure operation, suitable for orthopedic environments.

Ideal for Orthopedic Centers and Manufacturing Workshops

By integrating this machine, orthopedic centers can reduce their environmental footprint while gaining autonomy by repurposing used materials to produce new equipment at a lower cost.

also referenced under: OOMAGRAN300, CRM 78

Internal Reference:

132 W 000