An Innovative Recycling Process

Our machine is at the heart of an ingenious recycling process:

- Collection and Sorting: Used orthopedic prostheses, mainly made of polypropylene, are collected and sorted.

- Grinding: These devices are then ground into granules using a granulator.

- Injection: The granules are heated and injected into specific molds to create new mobility aids, such as crutches and forearm crutches.

This process helps reduce medical plastic waste while providing essential equipment to those in need.

Technical Features of the Machine

Our hydraulic injection machine stands out for:

• Versatility: Adapted for processing recycled polypropylene, ensuring high-quality finished products.

• Energy Efficiency: Designed for optimized energy consumption, contributing to sustainable production.

• Accessibility: Easy to use and maintain, making it ideal for workshops engaged in social and environmental projects.

Social and Environmental Impact

Our initiative offers multiple benefits:

• Waste Reduction: By recycling used prostheses, we reduce the environmental footprint of medical waste.

• Empowerment: The workshops of the Saint-Hubert Foundation provide people with disabilities valuable employment opportunities, enhancing their social inclusion.

• Affordability: The produced mobility aids are more accessible, making these essential devices available to a larger population.

Towards Sustainable Orthopedics

This approach aligns with a global trend toward making orthopedics more eco-friendly. Similar initiatives explore the use of recycled plastics to manufacture orthopedic devices, reducing plastic pollution while improving healthcare accessibility.

By combining technological innovation with social responsibility, ATP Supply Sàrl demonstrate that the medical industry can evolve toward more sustainable and inclusive practices.

A Reliable and High-Performance Vacuum Pump

Our water vacuum pump is specifically designed to meet the demands of orthopedic prosthetists and rehabilitation centers, particularly in low- and middle-income countries where cost-effective and sustainable solutions are essential. It offers:

• Suction capacity of 250 l/min at 0.1 bar counter-pressure and 4 bar water pressure.

• Eco-friendly technology, requiring no oil for operation.

• Simplified use with minimal maintenance, eliminating the need for complex lubrication.

• Robust design, ensuring long lifespan and high reliability, making it ideal for resource-limited settings.

This solution is particularly suitable for thermoforming of prosthetic sockets and orthoses, as well as other applications requiring precise and stable vacuum pressure.

How Does Our Water Vacuum Pump Work?

Operating Principle

Unlike traditional pumps that require oil, our model operates exclusively with a Venturi system powered by a centrifugal water pump, making it ideal for settings with limited access to costly maintenance services.

Vacuum Generation

Water is continuously pumped and projected at high speed into an injector, generating a strong and constant vacuum in the circuit.

Practical Applications in Orthopedics

• Thermoforming of prosthetic sockets

• Custom orthosis manufacturing

• Vacuum molding for composite resin lamination

A Positive Impact: Less Waste, More Efficiency

• Eco-Friendly: No oil vapor emissions, reducing environmental impact and making it suitable for eco-conscious organizations and NGOs.

• Cost-Effective: Lower maintenance, no need to replace filters or lubricants, making it affordable for rehabilitation centers in low-income countries.

• Quiet Operation: Reduces workshop noise, improving user comfort and creating a better working environment.

By integrating this water vacuum pump into orthopedic manufacturing processes in low- and middle-income countries, ATP Supply Sàrl offers an innovative, cost-effective, and environmentally friendly solution, ensuring high performance, durability, and accessibility where it is most needed.

High-Performance Convection Oven for Orthopedic Centers

This high-performance convection oven is specially designed for orthopedic centers, providing uniform and controlled heating for thermoforming plastic materials and drying plaster models. With its robust stainless steel construction, it ensures exceptional durability and efficient use in demanding environments.

Features & Benefits

• Advanced Convection Technology: Equipped with two powerful fans, ensuring even heat distribution across the entire working surface.

• Optimized for Thermoforming: Designed to work with external rings, ensuring optimal heating for plastic sheets.

• Durable and Robust Construction: Interior and exterior made of stainless steel, offering high corrosion resistance and easy maintenance.

• Integrated Support & Storage:

- Steel support frame for improved stability.

- Storage shelf for convenient plastic sheet organization.

- User Comfort: - Viewing window to monitor the process without opening the door.

- Ergonomic opening system reducing heat loss.

- Interior lighting for enhanced visibility during operation.

- Electronic Heat Control: - Precise temperature regulation for optimal heat management.

- Adjustable temperature range from 30°C to 200°C.

- Smooth Sliding System: - Aluminum sliding shelf, coated with Teflon sheets, mounted on ball-bearing rollers for effortless handling.

Delivered with:

• 2-year warranty on spare parts, ensuring easy maintenance and uninterrupted use.

With its intelligent design and advanced features, this convection oven is an essential piece of equipment for orthopedic centers, ensuring precise thermoforming and effective drying of plaster models, making it a key investment for professionals.

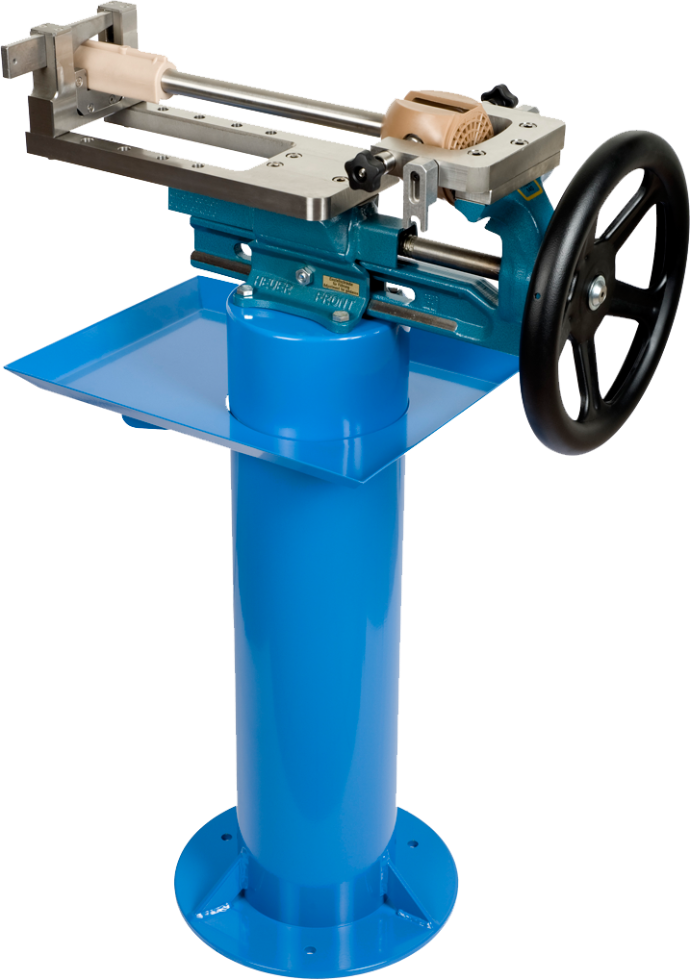

Knee Joint Insertion Press – Essential Tool for Orthopedic Centers

This knee joint insertion press is an essential tool for orthopedic centers, enabling precise insertion of knee joint tubes into Trans-Tibial and Trans-Femoral polypropylene modules. Designed for ergonomic and efficient use, it ensures optimal fixation while reducing the effort required for assembling prosthetic components.

Features and Benefits

• Precise and Secure Insertion: Ensures perfect alignment of the knee with the tube, minimizing assembly errors.

• Optimized for Trans-Tibial and Trans-Femoral Prostheses: Ideal for modular knee mounting on sockets.

• Robust and Durable Mechanism:

- Reinforced steel structure for increased resistance.

- Designed to reduce stress on components, preventing tube or joint deformation.

- Easy to Use: - Assisted insertion system, saving time and effort.

- Compatible with multiple prosthetic tube diameters.

- Adapted for Orthopedic Centers in Low- and Middle-Income Countries: - Reduces the need for complex tools.

- Increases the reliability of prosthetic assembly through uniform insertion.

Thanks to its robust and ergonomic design, this insertion press enhances the efficiency and precision of the prosthetic manufacturing and assembly process, ensuring reliable and reproducible results.